Dreams of Earth

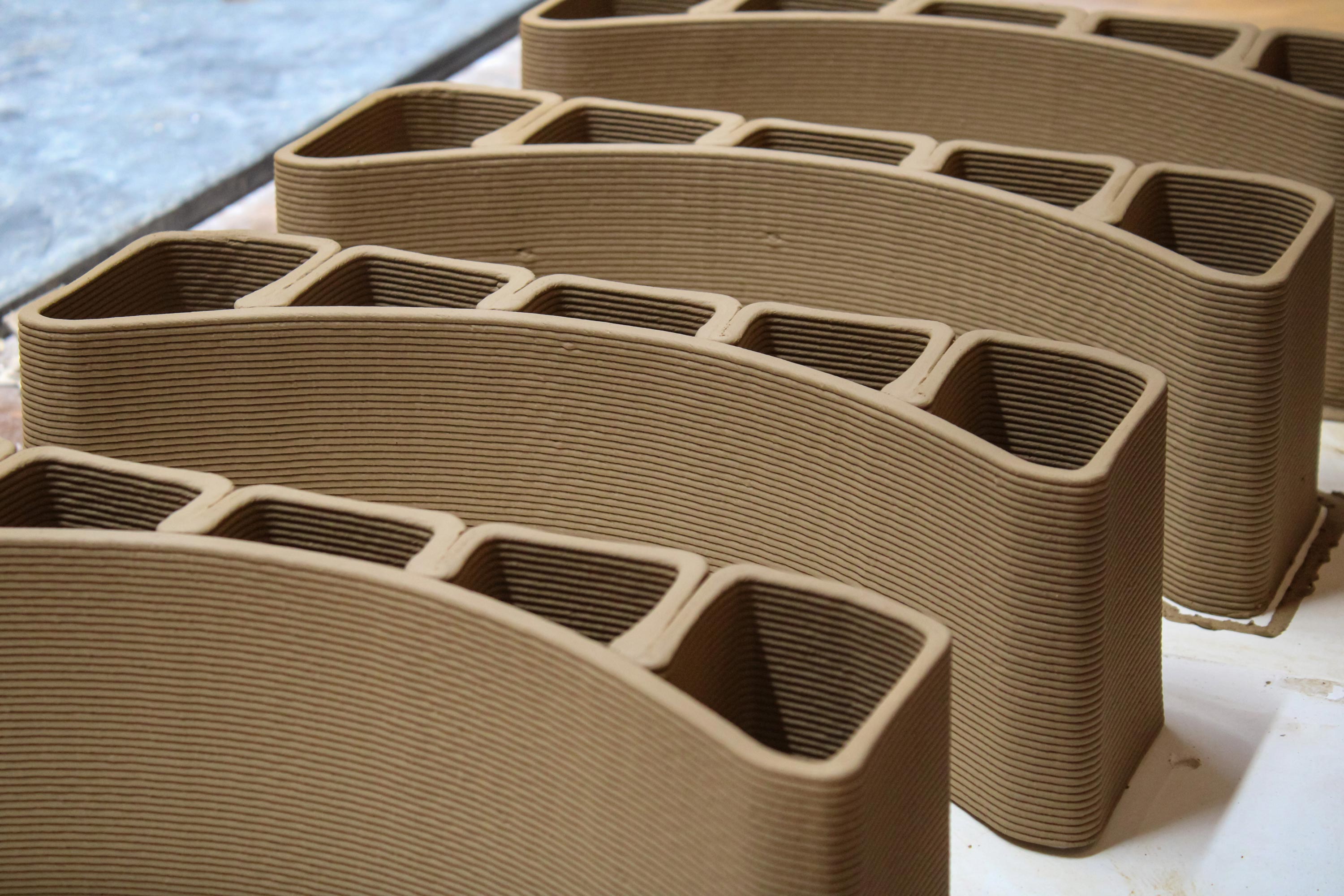

3D-printed clay blocks vault between precast concrete beams as lost formwork that enables the casting of a topping slab. The geometric flexibility of 3D-printing facilitates the production of mass customized ceramic block elements tailored to available materials and building design. Clay blocks are produced with local ceramic manufacturers using conventional clays and firing processes. The blocks themselves are lightweight and are optimized to minimize material usage and fabrication time.

The use of tepetate, a local soil with high contents of clay, allows for fabricating compressed, sun-dried blocks that constitute the pavilion walls. This affordable, low-carbon solution, which has been successfully applied in the construction of housing communities around Mexico for more than 30 years, is reinterpreted here with a post-tensioning system that allows for assembly and disassembly.

Publication

1. Curth, A., Brodesser, T., Sass, L. and Mueller, C. “Multi-objective optimization of vaults 3D printed without formwork,” Proceedings of the International Association for Shell and Spatial Structures (IASS) Symposium 2020/2021, Surrey, UK 2021.

2. A. Curth, B. Darweesh, L. Arja, and R. Rael, “Advances in 3D printed earth architecture: On-site prototyping with local materials,” presented at the BE-AM| Built Environment - Additive Manufacturing, TU Darmstadt, 2020.

3. A. Curth and A. Hartwell, T. Brodesser, and C. Mueller, "Parametric waffle slabs: Optimal geometry materialized with additive construction," Sept. 2022.

Prototypes are printed to calibrate the clay mixture, layer height and print speed for the bovedillas. Photo by Dinorah Martínez Schulte, 2022

Prototypes are printed to calibrate the clay mixture, layer height and print speed for the bovedillas. Photo by Dinorah Martínez Schulte, 2022 3D printed bovedillas using a mixture of clay from Oaxaca and Zacatecas. Photo by Dinorah Martínez Schulte, 2022

3D printed bovedillas using a mixture of clay from Oaxaca and Zacatecas. Photo by Dinorah Martínez Schulte, 2022 Local tepetate, cement, lime, and water are mixed to form Ecoblocks. Photo by Kiley Feickert, 2022

Local tepetate, cement, lime, and water are mixed to form Ecoblocks. Photo by Kiley Feickert, 2022